-

product

-

solution

with the development of 4k and above ultra-high-definition studio technology, major tv stations and production institutions are gradually evolving towards the st2110 protocol standard ip system in terms of new studios and broadcast trucks. colorlight launches the st2110 standard radio and television studio ip solution, which is perfectly compatible with the radio and television industry's requirements for ip and ultra-high definition. the integration of st2110 transmission and 5g+8k technology enables audio and video transmission and processing based on ip networks, enabling the most realistic display effects in broadcasting scenes such as radio and television studios and large stage display screens, and comprehensively improving the clarity of video images. accuracy and realism, while maintaining the stability and fluency of video playback, which will help the radio and television industry achieve digital and network transformation.

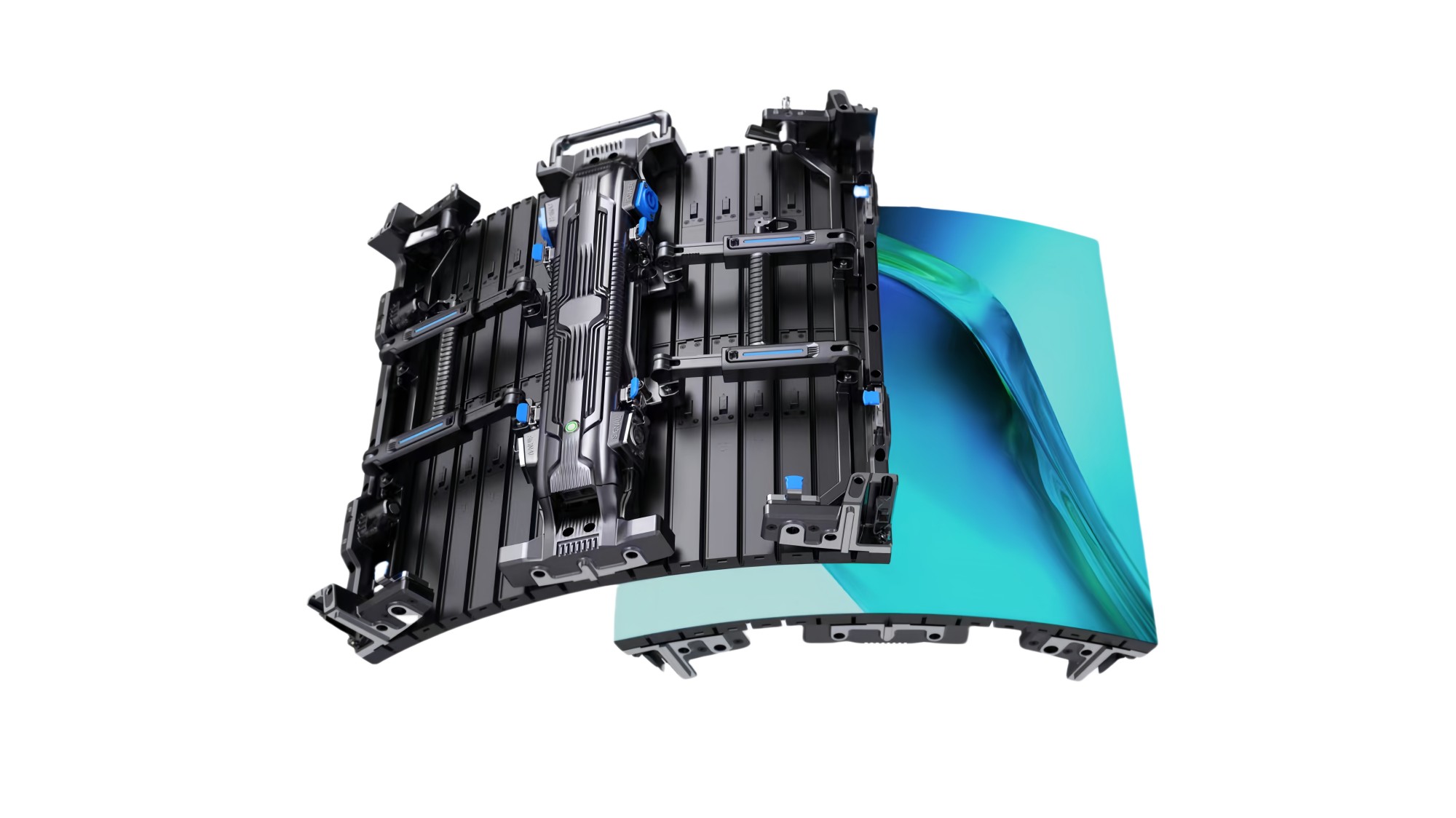

LED display being applied to create immersive and dynamic backgrounds, the LED virtual studio integrates high-configuration LED walls, camera tracking system and real-time rendering technology, and applies advanced technologies like motion capture, AR & VR, to complete virtual production without chroma keying and costly post-production.

Integrating communication, command, control & message into one, proven display solution for control rooms can present comprehensive information from different channels dynamically, responsively, and precisely for rapid decision making to deal with emergencies and significant events.

- case

-

support

一站式方案解决服务商,欢迎咨询

-

news

News Releases

-

about us

米奇智显是一家专业生产LED显示屏工厂,工厂集研发,生产,销售,施工一体化,一站式方案解决服务商,我们的理念:为客户创造价值,成就客户。

CertificationsCertificationsCertifications

Manufacturing BaseManufacturing BaseManufacturing Base

-

contact us

Service NetworkService NetworkService Network